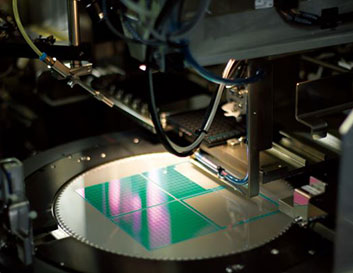

Available down to 0.8mm square. Please ask us for microfabrication.

It can also be cut along the pattern.

【Materials】

Float glass, optical glass, Pyrex, quartz glass, colored glass, silicon wafer, acrylic resin, polycarbonate, etc.

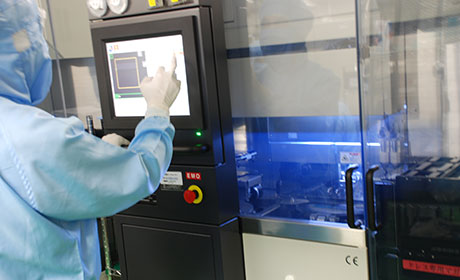

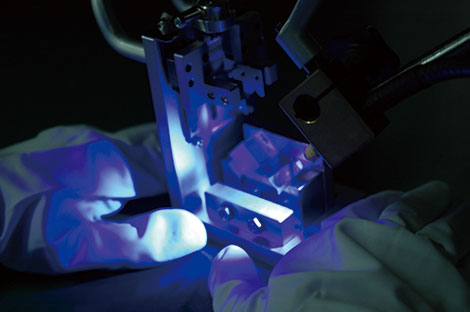

Cutting Processing with Dicer, Slicer, and Scriber

We cut the specified glass to the size you desire and provide it with the inspection data.

The following cutting methods, dicing, slicing and scribing are all available.

The production process is fully conducted in a clean room.

We support you from the trial manufacture to mass production in short delivery time and at a low cost.

Available down to 0.8mm square. Please ask us for microfabrication.

It can also be cut along the pattern.

Float glass, optical glass, Pyrex, quartz glass, colored glass, silicon wafer, acrylic resin, polycarbonate, etc.

In order to solve a dust problem that occurs during the product processing, we are fully equipped with the sorters which can operate tray packing from cutting without manual contact.

With being packed in a tray, the final delivery inspection is carried out with a microscope. It can detect even 10 micron dust. The inspected products are vacuum packed in a clean room and shipped.

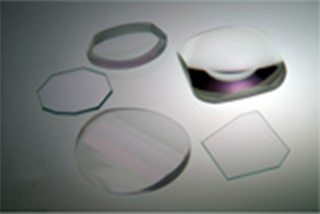

We can process high precision parts with flat and parallel surfaces as well as lens and prism with high- speed lapping and polishing machine.

Cutting: We can process materials into atypical shapes at the size of φ1 to φ360 mm with digital cam. e.g. D cut, atypical processing, polygonizing.

Polishing: We perform highly accurate specular working with double-sided polishing machine.

The mass production of lenses with high-speed polishing machine, or processing prisms with single-sided polishing machine are also available.

We have super white glass, BK7, both side polished, thickness 0.1~5.0 in stock.

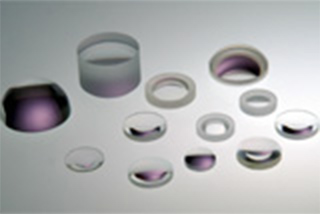

High precision glass adhesion, glass UV adhesion, optical contact

The high precision adhesion, bonding technology that is one of our core technologies has been highly acclaimed by our customers.

In addition to glass to glass bonding such as UV adhesion, optical contact, glass to resin adhesion is also available.

We propose the best bonding method and adhesives according to the specification, level of precision and application that customers require.

With UV curing method, we bond prisms or rods together with high precision (within 1 minute).

We can give you technical advice on selection of adhesives and bonding tools according to the level of precision and application that meet your needs.

Optical contact adhesion is a glueless process to join two high precision polished surfaces together by the intermolecular force of the substrates.

We also support air contact adhesion depending on the application that customers require.

In case of bonding two materials such as glass and resin, which have a difference in thermal expansion, peel-off is easily caused by physical forces such as shock, or environmental factors such as temperature, humidity.

Therefore it requires a great deal of time and effort to set conditions and select the best adhesives for bonding glass to resin.

However, we can manage this with our own know-how cultivated for years.